Hydrogen Fuel Tanks

Hydrogen Fuel Tanks

Since hydrogen-powered cars are still an emerging industry, so too are hydrogen fuel tanks for cars, trucks and other vehicles.

|

Hydrogen fuel tanks come in two main variety including those that contain compressed hydrogen gas and those that contain cryogenic hydrogen (super-cooled liquid hydrogen).

|

Hydrogen Fuel Tanks |

There is a third type that is uncommon which is a tank that holds a hydrogen slurry (a hydrogen-rich hydrogen compound). At this link you can read more about hydrogen slurries.

So, the most common hydrogen fuel tank for cars, trucks, buses and other vehicles is that which holds compressed hydrogen gas in a range of 3,600 psi – 10,000 psi. Most hydrogen fueling stations now days dispense compressed hydrogen gas at 5,000 psi and 10,000 psi or at both pressures.

There are only a few hydrogen fueling stations which dispense cryogenic liquid hydrogen. This is mainly because almost all of the major carmakers have chosen to fuel their prototype cars with compressed hydrogen gas. The one exception has been BMW as their Hydrogen 7 automobile uses cryogenic hydrogen and gasoline (it’s a dual fuel vehicle).

Cryogenic Tanks …

BMW used to have a boil off problem with their cryogenic hydrogen tanks which means that if you left the vehicle sit for a couple of weeks, say at the airport, the liquid hydrogen would find its way out of the tank and evaporate. BMW within the last couple of years has claimed to have solved this problem.

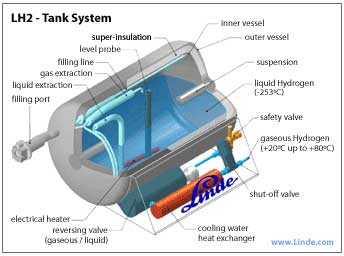

But there are other problems with cryogenic liquid hydrogen. To maintain liquidity, hydrogen has to be stored at a temperature at or below negative 253 degrees Celsius. The only way to maintain that temperature in a truck for transporting the liquid to fueling stations is to have a technologically advanced freezer system installed in the truck.

Liquid Hydrogen Tank |

In addition to the expense of the truck itself, the operating cost, especially the truck’s own fuel, would be large. Because liquid hydrogen is so cold, it is capable of freezing the air around it. This quality could cause the truck’s equipment to stall or degrade.

|

In regard to compressed hydrogen fuel tanks, most of these now days are made of some sort of carbon fiber composites or carbon fiber and metal alloys and composites.

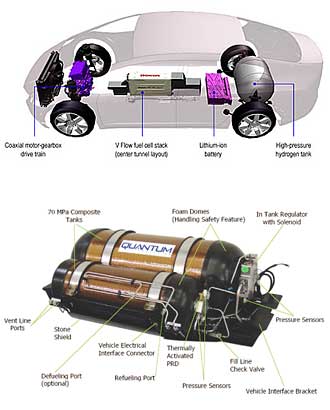

The U. S. Department of Energy says this about a hydrogen fuel tank developed by Quantum Technologies, “Carbon fiber-reinforced 5000-psi and 10,000-psi compressed hydrogen gas tanks are under development by Quantum Technologies and others. Such tanks are already in use in prototype hydrogen-powered vehicles. The inner liner of the tank is a high-molecular-weight polymer that serves as a hydrogen gas permeation barrier.

“A carbon fiber-epoxy resin composite shell is placed over the liner and constitutes the gas pressure load-bearing component of the tank. Finally, an outer shell is placed on the tank for impact and damage resistance. The pressure regulator for the 10,000-psi tank is located in the interior of the tank. There is also an in-tank gas temperature sensor to monitor the tank temperature during the gas-filling process when tank heating occurs.”

Now, what is inside the hydrogen fuel tank is also an area with several options. For instance, some manufacturers compress the H2 gas into open space. Other manufacturers are using metal hydride technology where hydrogen is stored the porous metal hydride material then the gas is released by adding a little heat to the tank. The drawback with using metal hydrides in hydrogen fuel tanks is that they are generally very heavy. This weight then cuts down on the MPG’s of the vehicle.

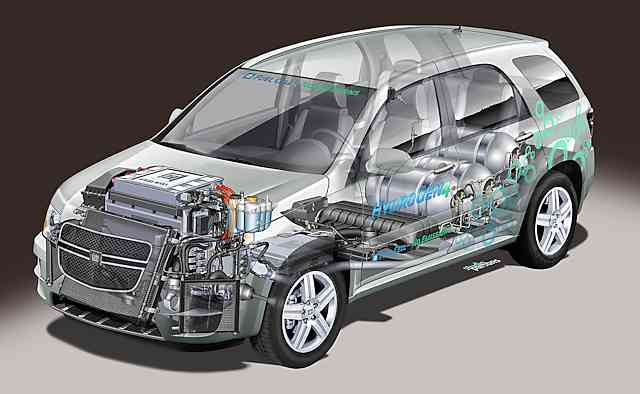

Hyundai Tucson FCEV showing fuel cell tanks

Nano Materials …

Manufacturers are also experimenting with other nano materials for storing hydrogen. Carbon nanotubes and various types of doped metals such as aluminum hold promise in creating lightweight hydrogen storage tanks.

Another issue of course is cost. Creating a 20-gallon fuel tank prototype from metal hydrides or carbon nanotubes can add up to $30,000 to the price of a car. However, scientists at the 13th Annual Green Chemistry and Engineering Conference in Delaware believe they have found an alternative to these costly materials.

Carbonized chicken feather fibers may be able to keep hydrogen from leaking out of a gas tank. This method would add only about $200 to the price of a car. Of course, much of the hydrogen fuel tank technology for cars is still experimental.

At one time Great Britain wanted to buy a number of Honda Clarities for police work. The caveat was that the compressed hydrogen fuel tanks had to be bullet proof. Honda succeeded in creating a handful of such H2 custom built tanks at great expense.

If hydrogen cars are to succeed in the marketplace it’s not only the price of fuel cells that needs to come down (with economies of scale of course). But hydrogen fuel tanks need to be lighter, hold more volume and cost less than they presently do.

Scientists and researchers are now working on this issue and as with many other technology driven challenges the future will most likely hold a variety of workable solutions.

Our Blog

Check out more info about hydrogen fuel tanks from our blog.

External Links

http://www1.eere.energy.gov/hydrogenandfuelcells/storage/hydrogen_storage.html

http://www1.eere.energy.gov/hydrogenandfuelcells/pdfs/mfg2011_plenary_leavitt.pdf

http://www1.eere.energy.gov/hydrogenandfuelcells/pdfs/compressedtank_storage.pdf

Written by Hydro Kevin Kantola

Leave a Reply

You must be logged in to post a comment.